The majority of connector failures result in intermittent connections or open contacts: Failure modeĬonnectors are purely passive components – that is, they do not enhance the function of a circuit – so connectors should affect the function of a circuit as little as possible. Housings or backshells can be made of molded plastic or metal. Ĭontact carriers that hold the parts of a connector together are usually made of plastic, due to its insulating properties. Thus, copper pins are usually coated with gold to alleviate these pitfalls, especially for analog signals and high reliability applications. For example, copper alloys have favorable mechanical properties for electrodes, but are hard to solder and prone to corrosion. The use of a coating material with good conductivity, mechanical robustness and corrosion resistance helps to reduce the influence of passivating oxide layers and surface adsorbates, which limit metal-to-metal contact patches and contribute to contact resistance. The base electrode metal is often coated with another inert metal such as gold, nickel, or tin. : 15 Alternatives include brass, phosphor bronze, and beryllium copper. Insulators must have a high electrical resistance, withstand high temperatures, and be easy to manufacture for a precise fit.Įlectrodes in connectors are usually made of copper alloys, due to their good conductivity and malleability. Properties important to conductor materials are contact resistance, conductivity, mechanical strength, formability, and resilience. : 6 Materials Įlectrical connectors essentially consist of two classes of materials: conductors and insulators. No single connector has all the ideal properties for every application the proliferation of types is a result of the diverse yet specific requirements of manufacturers. In some cases an equipment manufacturer might choose a connector specifically because it is not compatible with those from other sources, allowing control of what may be connected.

It is usually desirable for a connector to be easy to identify visually, rapid to assemble, inexpensive, and require only simple tooling. In addition to the classes mentioned above, connectors are characterised by their pinout, method of connection, materials, size, contact resistance, insulation, mechanical durability, ingress protection, lifetime (number of cycles), and ease of use. In computing, electrical connectors are considered a physical interface and constitute part of the physical layer in the OSI model of networking. Splice or butt connectors (primarily insulation displacement connectors) that permanently join two lengths of wire or cable.pin headers, screw terminals, board-to-board connectors) PCB mount connectors soldered to a printed circuit board, providing a point for cable or wire attachment.Chassis or panel connectors permanently attached to a piece of equipment so users can connect a cable to a stationary device.inline or cable connectors permanently attached to a cable, so it can be plugged into another terminal (either a stationary instrument or another cable).Electrical connectors can be divided into four basic categories, differentiated by their function: Thousands of configurations of connectors are manufactured for power, data, and audiovisual applications. An adapter can be used to join dissimilar connectors.

Cable connector portable#

The connection may be removable (as for portable equipment), require a tool for assembly and removal, or serve as a permanent electrical joint between two points.

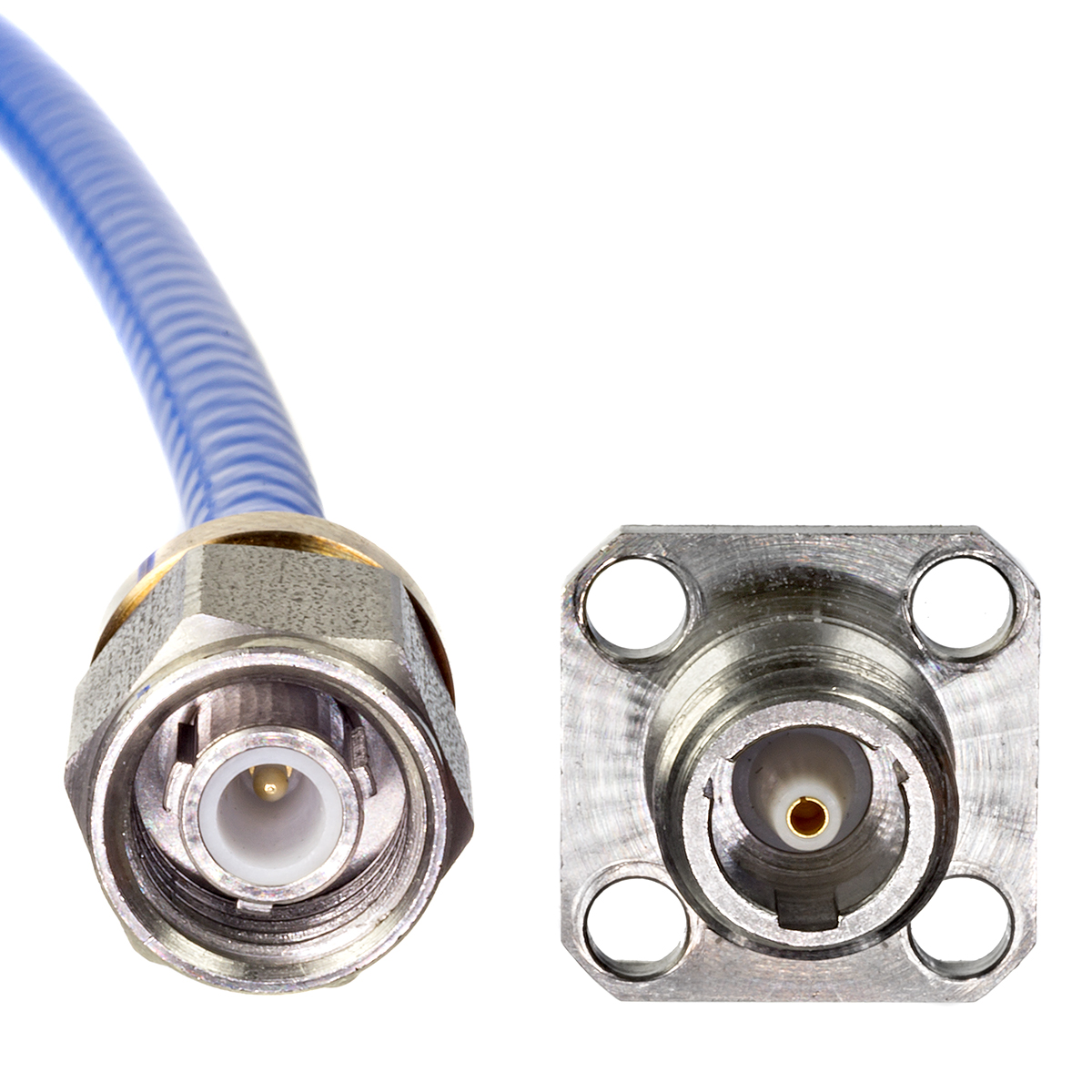

the male component, called a plug, connects to the female component, or socket. Most electrical connectors have a gender – i.e. Connectween parts of an electrical circuit, or between different electrical circuits, thereby joining them into a larger circuit.

0 kommentar(er)

0 kommentar(er)